“Combining the benefits of extreme versatility, uncompromising fire safety, and the strongest in sustainability”

What is Aluminum Composite Material?

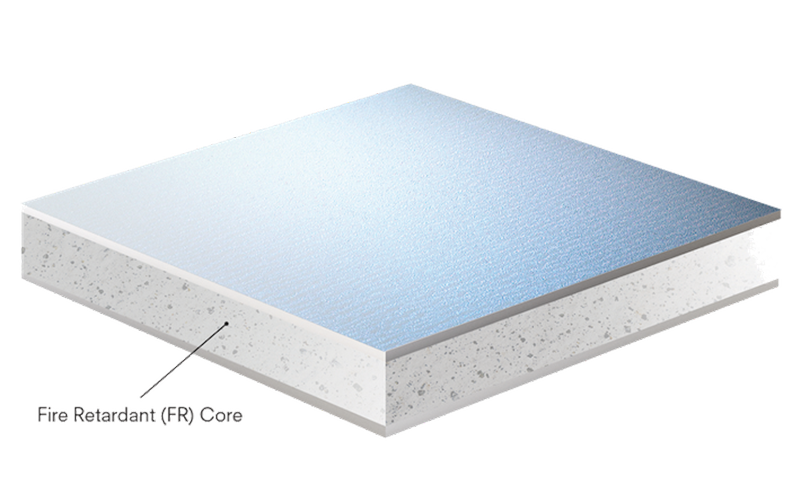

Fire-Resistant Aluminum Composite Panel is a composite material made of aluminum and non-combustible mineral filled core. Though the core material does contain a small amount of combustible polyethylene, the main ingredient of the non-combustible mineral filled core does not permit the proliferation of flame and restricts smoke. It is a fire-safe material that passes mandatory requirements for exterior and interior application. It is an ideal material for external claddings, roof of pedestrian passage and other architectural applications.

What Can CC Image Group

Do For You Today?

Let's get started with your project now. Reach out to our team to learn how architectural aluminum fabrication can set you apart.

The ACM and ACP difference.

Aluminum Composite Material (ACM) is in ever-increasing demand, as both the commercial and residential building industries seek both innovation and practicality in the marketplace. CC Image Group leads the industry in providing Aluminum Composite Panels (ACP) as a perfect solution for external cladding & facades, insulation, signage, and more.

ACM Panels are very durable as well as super resistant to inclement weather and staining. In addition to the visual impact of ACM Panels, those who use them for exterior cladding often find decreased noise levels from the outdoors in.

Rob Cooley | CEO

“Customers aren’t really customers, they are partners in the process.”

Start by checking out the premade demo websites to see what’s possible.

Salient is the ultimate WordPress theme for building beautiful websites.

Quick Links

Get In Touch

Request Your Quote

All Products

Portfolio

Warranty Information

Our Facility

CC Image Group | Architectural Aluminum Fabrication

Location

2009 Dorsey Rd.

Building G

Marietta, Ga. 30066

Contact

770.883.3506

“Thank you for your interest in our company. We look forward to speaking with you soon!”

Copyright

CC Image Group, Inc.

2021. All Rights Reserved

Digitally Marketed By

![]()